What Does AGM Battery Mean?

Understanding the technology behind Absorbent Glass Mat batteries

AGM Battery Definition

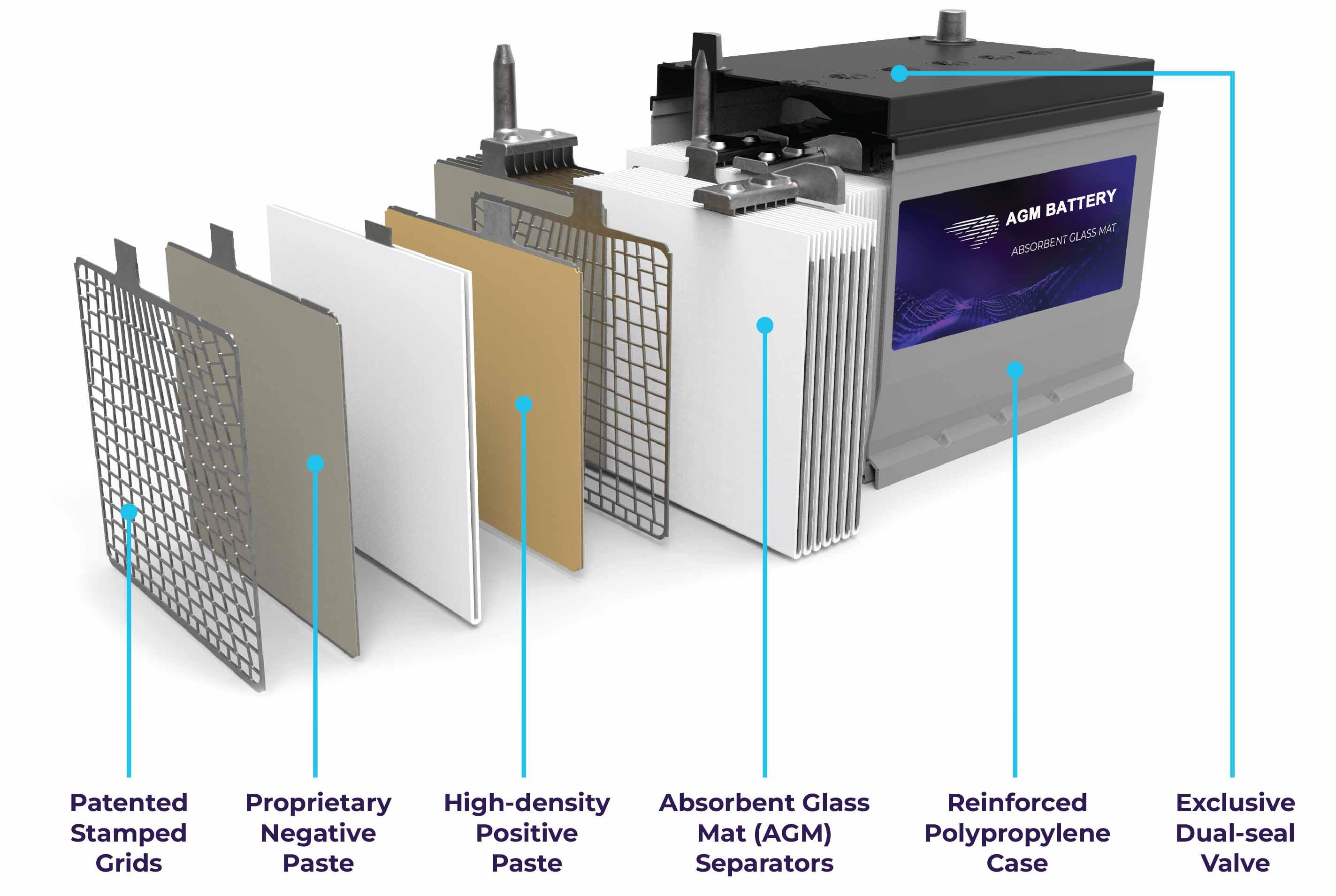

AGM stands for "Absorbent Glass Mat" - a type of sealed lead-acid battery technology where the electrolyte is absorbed into a fiberglass mat separator between the battery plates. This design eliminates the need for liquid electrolyte, making AGM batteries spill-proof and maintenance-free.

The absorbent glass mat acts like a sponge, holding the sulfuric acid electrolyte in place while allowing the chemical reactions necessary for battery operation to occur efficiently.

Key AGM Characteristics:

- Sealed, maintenance-free design

- Spill-proof and leak-resistant

- Can be mounted in any position

- Lower self-discharge rate

Sealed Design

No maintenance required